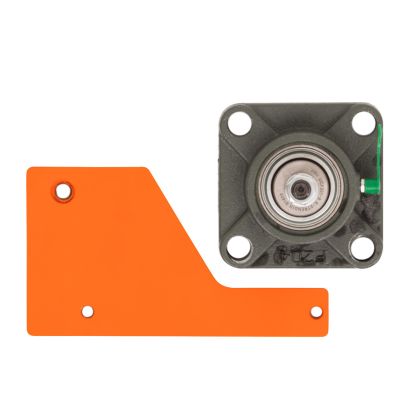

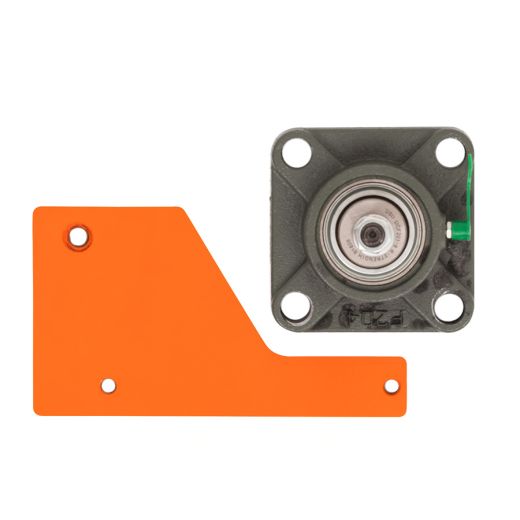

Mounting Plates & Rotary Bearings for Husqvarna Hipertrowel™

Product Highlights

- Available Attachments: A, B and C for the Husqvarna Hipertrowel polishing system

- Original Equipment Replacement Part

Product Description

Mounting Plate and Rotary Bearing for Husqvarna Hipertrowel polishing system.

As a specialist in polishing concrete floors, you sometimes need a faster polishing method than using a planetary floor grinder. Especially when you’re dealing with a really large, unobstructed area, where the surface flatness is already sufficient. The Husqvarna Hipertrowel™ system is exactly the solution you’re looking for.

We combine our expertise in concrete floor polishing, our superior diamond tools and advanced driver technology for trowels to create a functional polished concrete floor obtained at the speed of ride-on trowel finishing.

WHAT TYPE OF PROJECTS ARE SUITABLE?

The Hipertrowel™ method is ideal for industrial floors from 500 m² and up. Both newly poured slabs and older, pre- existing floors can be processed with the Hipertrowel™ system.

WHAT END-RESULT CAN YOU PRODUCE?

The Hipertrowel™ system allows you to produce a nicely salt and pepper-looking floor with a satin or glossy finish.

HIPERTROWEL™ IS THE IDEAL SOLUTION WHEN :

- Time is the most critical parameter

- The surface is 500 m² or more

- There are no obstacles (pillars etc.)

- The floor does not need to be levelled

- No aggregate needs to be exposed

- Wet grinding is not an issue

- A good slurry management system is on site

IT’S FAST AND EASY TO POLISH LARGE CONCRETE FLOORS WITH THE HIPERTROWEL™ SYSTEM

HOW DOES IT WORK?

The Hipertrowel™ method is a wet polishing process in six steps (#30G – #600G), and three optional final steps (#800G – #3000G). Depending on the conditions of the floor, initial grinding and grouting with a planetary grinder might be recommended.

TOOLS AND EQUIPMENT

Your Husqvarna retailer will provide you with a complete setup of Hiperflex TRW tool pads, chemicals, Hipertrowel™ gyro drivers and power trowel attachments. You’ll also need a ride-on power trowel, a squeegee vacuum to collect the slurry and a water hose connected to a tap. For maintenance, we highly recommend the Husqvarna Hiperclean pad. - Additional grit sizes are available

YOU’LL ALSO NEED :

- Ride-on power trowel, 36 or 48 inch

- Pressurized water tap

- Slurry disposal solution

- Wall protection plastic cover

- Autoscrubber

FLEXIBLE GYRO DRIVER TECHNOLOGY FOR EXCELLENT RESULTS

All parts in the Hipertrowel™ system are interacting to secure that the whole floor is evenly polished by the diamond tools at each passage of the machine to create a homogenous finish of the floor.

MAXIMUM FLEXIBILITY

Both the Hipertrowel™ gyro driver and Hiperflex TRW tool pads are designed for maximum flexibility in all directions. This allows the diamond tool pucks to follow the floor surface in the high and low spots and create a homogenous salt and pepper finish.

MULTI-ORBITAL ROTATION

The Hipertrowel™ gyro driver has a floating bearing mount that allows it to rotate independently of the trowel rotor. This solution enables a more efficient polishing process with a more consistent scratch pattern.

EVEN TOOL WEAR

The flexible polymer backing ring adjusts to unevenness of a floor and ensures an even wear on the pucks and ultimately a longer life of the tooling.

HASSLE-FREE MAGNETIC MOUNT

The Hiperflex TRW tool pads are easy to mount securely underneath the Hipertrowel™ gyro drivers due to strong magnets connecting the pads to the driver.

OPTIMIZED TOOL DESIGN

The proven technology of the renown Hiperflex tools has been further developed to fit the demands of a ride-on power trowel. For example, the number and position of the pucks are calculated to ensure optimal results and maximize tool life.

Technical Specifications

| Brand | Husqvarna |

|---|---|

| Category | Bearings |

| Condition | new |