OSHA's New Crystalline Silica Standard

What are the new limits on respirable crystalline silica?

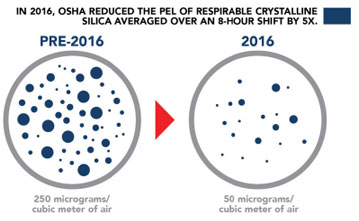

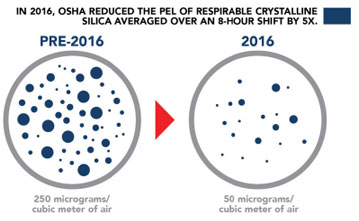

OSHA’s new standards on respirable crystalline silica in the workplace significantly reduce the permissible exposure limits (PEL) from 250 ug/m3 to 50ug/m3 over an 8-hour time-weighted average (TWA). The new rules went into effect on June 23, 2017 and enforcement began on September 23, 2017. Crystalline Silica Standard 29 CFR 1926.1153 applies to all exposures of respirable crystalline silica, except where exposure will stay below the OSHA action level of 25 ug/m3 over an 8-hour TWA.

So if your workplace actvity generates more than 25 ug/m3 over an 8-hour TWA, you MUST follow the new OSHA regulations.

This includes (but is not limited to) activities such as

- Concrete grinding and polishing with walk-behind or handheld grinders

- Joint cuttng with handheld or walk-behind saws

- Tuck pointng

- Shot blasting

- Concrete drilling

Bottom Line: All concrete operators who grind, cut, or polish concrete, sand, mortar, block, terrazzo, and natural stone must follow the new regulations or risk incurring heavy fines.

OSHA Crystalline Silica Standard Resources

VIDEO: Top 4 Reasons Why You Should Care about OSHA’s New Silica Rules

You may be surprised to find out how the new rules from OSHA will affect your business. In this short video, we’ll explain the top four reasons why you shouldn’t ignore the new standards.

Get Help Ensuring ComplianceAdditional Crystalline Silica Standard Videos

You might think all you need to do is provide respirators to your team while they work, but OSHA’s rule specifies that employers must first implement engineering controls to reduce their employees exposure to respirable crystalline silica.

Some examples of engineering controls include:

- Using water while grinding to limit airborne dust

- Using a dust shroud when possible

- A properly sized dust collector with 99% air filtration

- Correct housekeeping procedures (use a HEPA-filtered vacuum to remove worksite dust instead of a broom or air compressor)

When these types of engineering controls aren’t enough to reduce workers’ exposure to crystalline silica, then respira-tory protection must be provided. Respirators must comply with the requirements of the silica standard and with OSHA’s Respiratory Protection standard (29 CFR 1910.134).

Find out what else you need to know about respiratory protection on the job site…

OSHA's New Crystalline Silica Standard

What are the new limits on respirable crystalline silica?

OSHA’s new standards on respirable crystalline silica in the workplace significantly reduce the permissible exposure limits (PEL) from 250 ug/m3 to 50ug/m3 over an 8-hour time-weighted average (TWA). The new rules went into effect on June 23, 2017 and enforcement began on September 23, 2017. Crystalline Silica Standard 29 CFR 1926.1153 applies to all exposures of respirable crystalline silica, except where exposure will stay below the OSHA action level of 25 ug/m3 over an 8-hour TWA.

So if your workplace actvity generates more than 25 ug/m3 over an 8-hour TWA, you MUST follow the new OSHA regulations.

This includes (but is not limited to) activities such as

- Concrete grinding and polishing with walk-behind or handheld grinders

- Joint cuttng with handheld or walk-behind saws

- Tuck pointng

- Shot blasting

- Concrete drilling

Bottom Line: All concrete operators who grind, cut, or polish concrete, sand, mortar, block, terrazzo, and natural stone must follow the new regulations or risk incurring heavy fines.

OSHA Crystalline Silica Standard Resources

VIDEO: Top 4 Reasons Why You Should Care about OSHA’s New Silica Rules

You may be surprised to find out how the new rules from OSHA will affect your business. In this short video, we’ll explain the top four reasons why you shouldn’t ignore the new standards.

Get Help Ensuring ComplianceAdditional Crystalline Silica Standard Videos

You might think all you need to do is provide respirators to your team while they work, but OSHA’s rule specifies that employers must first implement engineering controls to reduce their employees exposure to respirable crystalline silica.

Some examples of engineering controls include:

- Using water while grinding to limit airborne dust

- Using a dust shroud when possible

- A properly sized dust collector with 99% air filtration

- Correct housekeeping procedures (use a HEPA-filtered vacuum to remove worksite dust instead of a broom or air compressor)

When these types of engineering controls aren’t enough to reduce workers’ exposure to crystalline silica, then respira-tory protection must be provided. Respirators must comply with the requirements of the silica standard and with OSHA’s Respiratory Protection standard (29 CFR 1910.134).

Find out what else you need to know about respiratory protection on the job site…