Do you own a microbrewery? Whether running the show or renting your commercial space out to a local brewmaster, the flooring system you install is critical to your microbrewery’s success. And we want to support you from the ground up — literally!

In the guide, we’ll walk you through the importance of installing the proper flooring system in your brewery, which system is best suited for you, and how to install it correctly. We’ll cover a few maintenance tips and best practices, too.

When looking for the perfect floor for your booze business, here are seven "rules" to keep in mind:

1: Look Cute (with or without Beer Goggles)

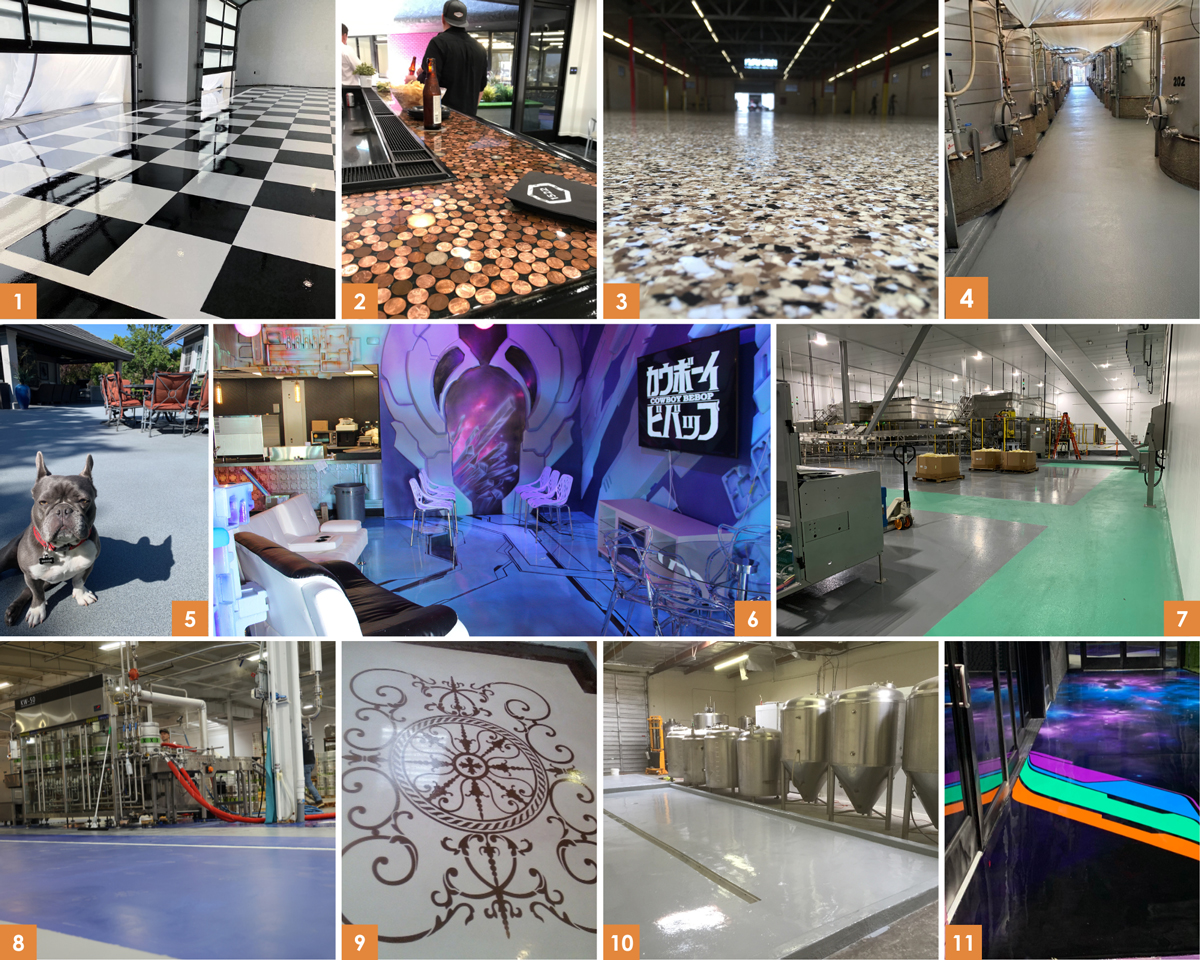

First and foremost, you want your floors to look good even if your customers never see them. Resinous coatings offer plenty of options to match your style and brand. By incorporating your favorite colors, logo, metallic pigments, or colored aggregates, you can make the floor as eye-catchingly sexy or low-key as you like.

2: Make Friends in Low Places…with Proper Drainage.

What spills in the brewery, stays in the brewery. Unless you have proper drainage.

Your best bet when it comes to brewery floor drains is something linear and corrosion-resistant with a U-shaped bottom. Our co-favorites are the wide-bottomed trench drain and the teardrop-shaped slot drain.

Trench drains come in various widths and allow more wastewater and solids (spent grains, fruit, yeast) to pass through. But they do require grates that need regular cleaning and can be damaged by heavy forklifts and equipment. On the flip side, slot drain openings are so narrow they don’t require a grate, so can handle heavier loads, and require less cleaning. But they can’t accept as much beer waste.

Our advice? You can play the slots for a low-maintenance option. But if you’re planning on some major beer-flowing action, our money’s on the trench.

No matter which drain you choose, make sure your floor slopes toward it so you can say bye-bye to puddles — aka slip hazards; aka breeding grounds for slimy bacteria. Speaking of the little slimies ...

3: Don't Let Microbes Stay for Happy Hour

Think of corners, cracks, and crevices like skeevy dive bars for bacteria and fungi — easy places to hide, drink up, and grow fat on stale peanuts.

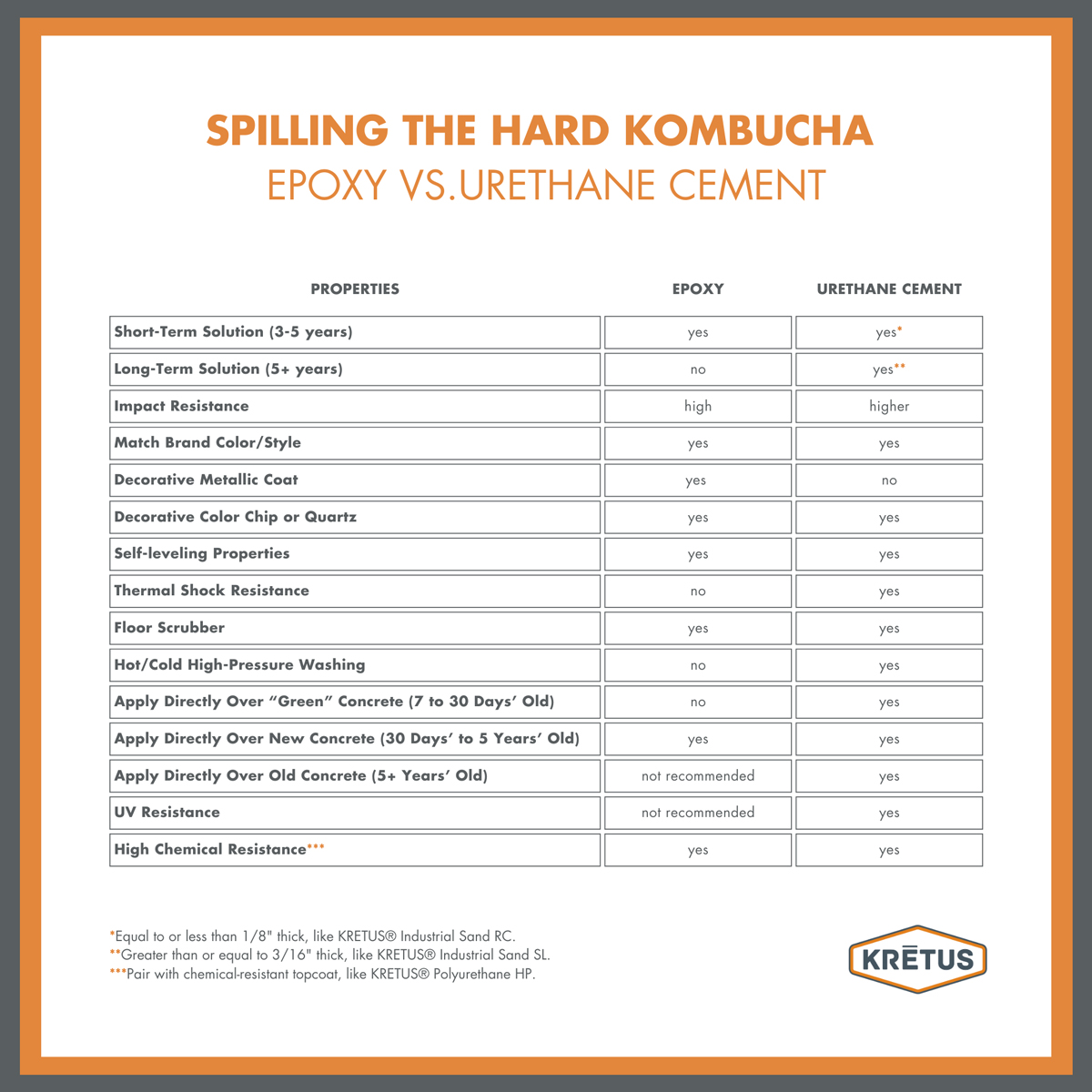

Opt for seamless, non-porous resinous coatings, like KRETUS® Top Shelf® Epoxy or Urethane Polymer Concrete SL, to cut back on where these filthy little barflies hang.

4: Handle Your Alcohol Process

The floor coating you choose has to keep up with your business. Brewing beer, mulling wine, and distilling spirits involve some heavy cask and keg lifting, spills, intense temperature changes, and constant foot and forklift traffic. To keep the day-to-day wear-and-tear in check, install a floor coating that resists damage from impact, moisture, thermal shock, and continuous traffic.

Pro tip: "Put urethane concrete down before you install tanks and heavy equipment. And don’t go cheap in back-of-house areas," says Kretus Vice President Jeremy St. Clair. "I've seen breweries use concrete polishing and sealers because they didn’t want to pay for urethane concrete. Within a year, the concrete was spalling and cracking. There were fruit flies everywhere. If they decide to install urethane concrete after the fact, their cost now doubles because they need to move thousand-gallon tanks out of the way."

5: Wave Goodbye to (Chemical) Hangovers

Like binge drinking on an empty stomach, chemical spills can leave a nasty mess on the floor. Malt enzymes, yeast, salt, vinegar, disinfectants, and other chemicals popular in the beverage-making industry can degrade and stain some floor coatings. The good news is that chemical-resistant topcoats like KRETUS® Polyurethane HP exist to protect your floors from this kind of thing.

6: Just Say No to “Bottoms Up” with Good Slip Resistance.

Avoiding a whoopsie-daisy when you’re in the business of making slippery (and delicious) liquids is incredibly difficult. To keep your employees and patrons safe from embarrassing and potentially harmful falls, add high-grip surface texture granules, like KRETUS® Anti-Slip, to your topcoat.

7: Lower the Bar … on Maintenance!

While I was working in my 20s, I used to open and close a dark and dirty little bar in Indianapolis. Now, whenever I see a string mop soaking in a yellow bucket of floor juice, I get weirdly nostalgic. But not so nostalgic that I'd go out and buy my own string mop. Have you ever cleaned with one of those things? They're disgusting. They just spread the dirt around. And good luck cleaning under the rolling coolers. I can't imagine cleaning an entire brewery with one of those.

Do yourself a favor and employ a more effective cleaning method. Choose a floor that can withstand high-pressure washing and a floor scrubber.

Brewery Floor Installation Tips

Planning the Installation

Before you get started, schedule a meeting with everyone involved in your installation — facility owner, architect, designer, specifier, contractor, and applicators — to lay out the steps in the installation project from start to finish. Review any points in the timeline where a negative outcome, such as concrete testing poorly, could lead to delays.

Testing the Concrete and the Installation

To prevent wasting money on a poor installation, inspect the site, complete all concrete moisture testing, and test the coating system in a small area onsite.

Moisture levels in concrete help your installer know whether the concrete is good, bad, or ugly. If it’s bad, it may require a moisture vapor barrier, like KRETUS® Top Shelf® Epoxy MVR, or additional crack and joint repair before the flooring system can be installed. If it’s ugly, it may require resurfacing or even replacement. Whatever the case, it’s better to do the fixes upfront. Bad or poorly prepared concrete will ruin a good coating.

Testing the system helps you see if it’s adhering properly to the concrete and whether you’re happy with the look of it.

Surface Preparation

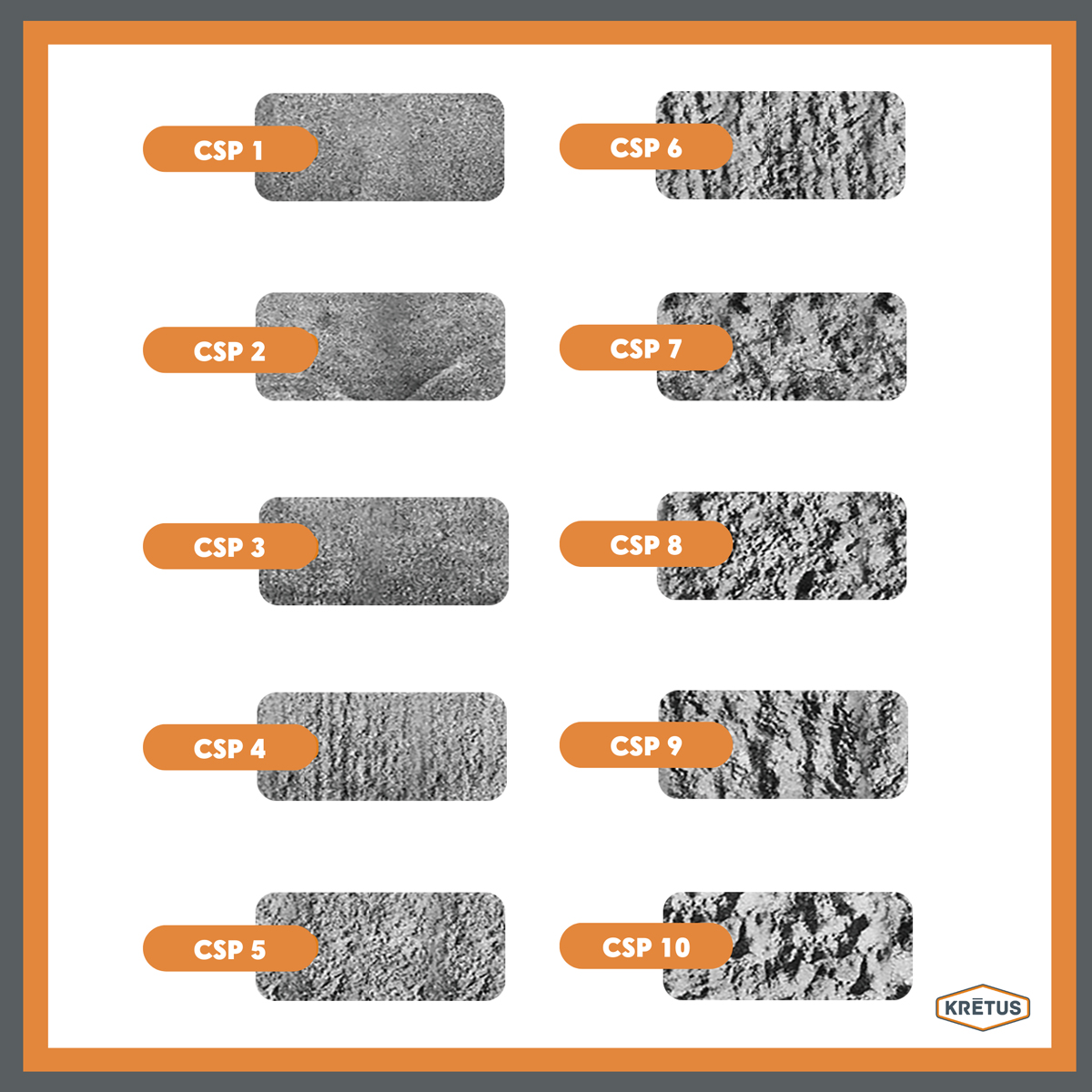

All concrete repairs must be completed, and the concrete will need to be mechanically profiled so that the coating can adhere to the surface.

The measurement for concrete surface profiles (CSP) is defined by the International Concrete Repair Institute (ICRI). Seamless coatings usually require a CSP ranging from 1, for concrete polishing, to 3, for epoxy and urethane cement. The higher the number is, the rougher the concrete surface profile will be.

How to Clean and Maintain a Brewery Floor

Daily Routines

Hose and power wash away spills and waste daily and after every batch. You can find an in-depth cleaning guide at kretus.com.

Watch for Tank Overflow

Don't let yeast, beer, and other chemicals sit on the coating for more than 24 hours. Spray those down the drain.

Shelve the Excess

Having extra coating products on hand makes upkeep easy. If your brewery floor gets damaged, you can repair these areas in-house. Tip: A variegated color scheme helps hide the patchwork.

And if you decide to expand your brewery, you’ll have the right flooring materials to coat the new sections to match the old. You can learn how to install brewery flooring by attending one of the KRETUS® training classes at Jon-Don.

Quick Guide Summary

- Pick a floor coating that fits your business. Use heavy-duty coatings in production areas and lighter-duty, decorative coats in customer service areas.

- Choose colors and designs that match your brand and style.

- Plan your installation timeline.

- Test the concrete. Then test the systems you’re installing in small areas onsite.

- Get proper drains installed and your flooring sloped toward them.

- Prepare the concrete and install floor coatings before installing brewery equipment.

- Execute your easy-breezy maintenance plan.

Products for Brewery Cleaning and Maintenance

Keep your newly installed brewery floor looking its best for years to come with these products:

- MotorScrubber Jet3 Handheld Scrubber

- Dirt Wacker Tile & Grout Cleaning Floor Machine

- Turbo Force Raptor Hard Surface Tool Quick Disconnect

- Turbo Force Hybrid Tile & Grout Cleaning Tool, 12 Inch

- Prospector® PE1200 Carpet & Hard Surface Extractor, 1200 PSI

- Bulldog Floor Scrubber from FCE by Jon-Don

Have Questions About Brewery Flooring? Talk to the Experts at Jon-Don!

Big or small, Jon Don has everything you need to tackle brewery floor coating and cleaning including equipment, supplies and expert guidance. Choose from a large selection of resinous coatings from top brands, like KRETUS® — with same-day shipping on most products.

Shop online 24/7 at JONDON.COM or call 800-556-6366 to speak with a Concrete Expert today!

About the author:

Jes St Clair is a writer, editor, designer, and humorist. She's worked in the coatings industry as a technical communicator with Kretus, Inc. since 2017. When not writing about thoughtfully designed coatings, Jes enjoys hiking California, crocheting, and eating copious amounts of ice cream. Her email address is jesika@kretus.com.

Comments