Cold storage facilities are critical for storing temperature-sensitive goods (and notorious for giving hot-headed chefs a place to cool off). They allow businesses to extend the shelf life of their products, maintain product quality, and comply with regulatory requirements. However, the temperature restrictions of walk-in freezers pose some challenges for coating installers.

In this article, we’ll discuss cold storage facilities, like walk-in coolers, freezers, and other commercial refrigeration; the different coatings that can be used on their floors; and how those coatings should be installed.

What Is Cold Storage and Why Is It Important?

According to market researchers, U.S. cold storage is expected to reach $96.9 billion by 2030. This is not particularly surprising when you consider the various types of walk-in refrigeration. Cold food storage, for example, preserves everything from mint chocolate chip ice cream and dinosaur-shaped chicken nuggets, while other coolers and freezers store blood donor platelets and rubella vaccines.

Non-food items, like medical supplies and chemicals, need to be kept at specific temperatures to remain stable. In the food and beverage industry, cold storage helps slow down the growth of microorganisms and enzymes that can cause deterioration.

In short: Cold storage keeps us healthy and safe.

And if you’re snowed in at The Stanley Hotel in a 1980 horror film, cold storage is the best place to trap (if only temporarily) your murderous husband, Jack Torrance.

Cold Storage Types and Temps

Facilities for cold storage range from walk-in coolers (like the one in Stanley Kubrick’s "The Shining") to large-scale warehouses with advanced temperature control systems.

Like their size, cold storage temperatures vary depending on the goods being stored. Because of this, a refrigeration system will generally fall into one of these three categories:

- Chilled: 32°F to 59°F (0°C to 15°C)

- Frozen: -0.4°F to -13°F (-18°C to -25°C)

- Deep-frozen: Below -13°F (-25°C)

With a vast difference in cold storage temperatures, contractors have a lot to consider before selecting the right coating for the facility.

Installation Tips for Cold Storage from KRETUS® Coating Experts

Dealing with Extreme Cold

Walk-in freezers are cold, so be sure to get clear on temperatures before doing a job walk and clarify whether they’re measuring temperatures in Celsius or Fahrenheit.

Michael Mulnix, the Western Territories Technical Product Manager at KRETUS®, learned this the hard way: “On one job, I thought they said it was going to be ‘40 or below’ or ‘40 and below,’ but it was 40 degrees below. It was cold. Guys were going in and out on forklifts … with their beards frozen to their faces.”

So, be prepared to wear layers—lots of them! Samet Dy, the Eastern Territories Technical Product Manager at KRETUS®, recalls one job he attended while bundled in THREE jackets. “And I was still cold!” He laughs. “Under 40 degrees is no joke.”

Checking Regulations

Consider the Building Materials Red List of chemicals and look for coatings for the walk-in freezer flooring that have little to none of the Red List ingredients, like KRETUS® Urethane Polymer Concrete. Also, make sure your coatings can meet regulation standards, like SCAQMD, FDA, and USDA.

For low-emitting VOC coatings, look for those made in Southern California, which sets low limits on VOC. “All of our coatings have been MAS Green Certified for the California Department of Public Health,” says Jeremy St. Clair, vice president of KRETUS®, which manufactures in Orange County, CA.

Profiling Concrete Substrates

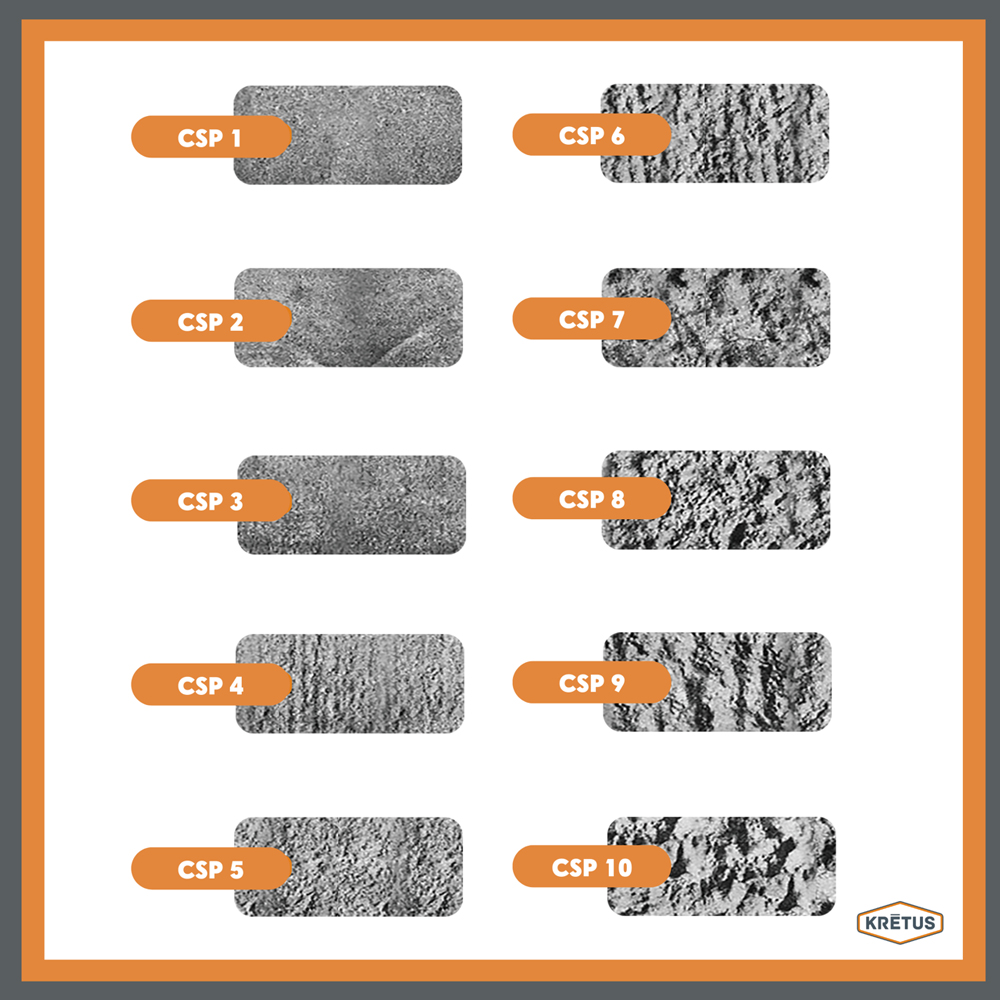

In general, you’ll want to mechanically profile concrete to a CSP of 3 (or 4 or 5 if the concrete’s in exceptionally poor condition). But profiling gets tricky when you’re installing in temperatures below -25°C because extreme cold can destroy concrete.

To keep the concrete from fracturing, these deep-freeze storage facilities typically have a heating system running underneath or through the concrete floor. In these instances, it’s best to check with the facility owner and the coating manufacturer to help you decide which tools will be best for the job.

“When you’re doing a deep-freeze application, the profiling can be very cumbersome,” Dy says. “In one environment, we did a diamond brush blast because the owner didn’t want heavy machines or shot blasting on the floor. The grind had to be the bare minimum.”

"Be aware, too," St. Clair adds, "that areas around the cooler doors may require a more aggressive surface profile. Especially if the cold storage is running while the installation is taking place. Because temperatures are constantly changing as you cross the threshold from warm air to cold."

Mixing Techniques with Fast-Cure Products

Where you mix the products becomes critical in cold temperatures. "When you’re installing at 40 degrees below, it’s hard to know if the material has cured or if it’s just frozen," Mulnix says.

In deep-freeze situations, 2x fast-curing hardeners—like KRETUS® XXFC products—should be mixed inside the cold storage unit. Otherwise, the material could harden before it leaves the mixing bucket.

Temperatures inside the storage facilities may be too cold for some coating components to chemically react and the coating may never harden. For fast-curing hardeners—like KRETUS® FAST, FC, or XFC products—mix the coating outside of the storage unit.

KRETUS® also specializes in custom formulations. So, if your application temperatures are outside of those recommended, contact a Jon-Don expert for help in selecting the right KRETUS® product for your cold storage job at 800-556-6366.

If you’re unfamiliar with resinous coatings, talk to an expert before you start the installation. “We’re here to help,” says Mulnix.

Detailing Terminations, Slopes, and Drains

All coatings should be properly sloped toward drains. Pay special attention to termination points, around poles, thresholds, and where the wall meets the floor.

“I’ve seen people struggle with transitions where metal meets concrete,” says St. Clair, “especially around drain pans. They’ll coat over both the concrete and the metal, and because these two substrates expand at different rates, the coating will inevitably crack.”

So, what should you do instead? “Coat up to the metal. Saw-cut a termination joint around the metal and then caulk the joint. Caulk is flexible enough to move with the substrates.”

Installing Coatings While the Cold Storage Is in Use

Ultimately, the facility is responsible for properly handling its temperature-sensitive goods. Because food cold storage is heavily regulated, the facility may choose to quarantine the installation area and remove all goods before the project begins.

If goods remain in the installation area, make sure to work this out with the facility owner before the installation begins. Ask them to protect the goods before the installation. A plastic sheet may be all that’s necessary, but your best bet is to ask the facility owner for their handling procedures before you take action.

Do not allow temperatures to decrease until the installation is complete.

Defrosting Pre- and Post-Installation

If defrosting is part of the installation process, the defrost period typically lasts three days. During this period, facility owners must remove everything from the cold storage facility, dehumidifiers must be brought in, and all water and condensation must be removed before the installation can begin.

Cooling Down

Once the installation is complete, temperatures should be dropped by 10°F every hour until the storage facility reaches the optimum temperature.

Washing Up

“One last thing,” Mulnix adds, “never, ever use enzyme cleaners to clean your resinous floors. I know they’re popular in the food and beverage industry, but resinous coatings are organic—so those little enzymes will literally eat that coating right off your floor.” Instead, use pH-neutral cleaners designed for concrete to keep your floors in good condition.

Like all resinous floors, maintenance is the key to success. Keep up your daily cleaning. Don’t allow spills to sit. Fix cracks, gouges, and scratches right away. Have the coating inspected by a professional every two years. And if necessary, recoat with a maintenance topcoat.

Coating Systems for Cold Storage

Beyond their variance in temperature, cold storage facilities have other risks that make resinous coating systems ideal:

- Low ambient humidity: If the storage facility will be in use, look for resinous coatings that can tolerate low humidity during installation.

- High humidity/moisture during defrosting: Resinous coatings are great for waterproofing.

- Power outages causing spoilage or microbial growth: Resinous coatings are seamless, mitigating the risk of bacterial and fungal growth.

- Hot pressure-washing: Look for coatings with thermal shock resistance.

Expert Recommendation: Sand Broadcast Systems, such as KRETUS® Industrial Sand Systems

We recommend sand broadcast systems, such as the KRETUS® Industrial Sand System. Our experts have listed a few key featured below as well as the coatings that make up this option:

- Price: Higher one-time installation cost, lower upkeep costs.

- Application: 3-4 coats

- Durability/longevity: High

- Maintenance: Low

- Impact resistance: High

- UV and chemical resistance: Low to high

Urethane Cement, such as KRETUS® Urethane Polymer Concrete

Pros:

- Low odor

- Low maintenance

- Withstands hot pressure washing

- Thermal shock resistant

- Fast drying options

- Can be installed over concrete that is 7 days to 5+ years old

- Tolerates high moisture (15-25 lbs MVER)

Cons:

- Must wait 5-7 days before heavy-duty traffic and cleaning

Epoxy, such as KRETUS® Select OMG Blocker

Pros:

- Low maintenance

- Low odor

- Fast drying

- Tolerates high condensation and moisture (15-25 lbs MVER)

Cons:

- Cannot use hot pressure washing

- Must wait 5-7 days before heavy-duty traffic and cleaning

Polyaspartic, such as KRETUS® Polyaspartic

Pros:

- Low to mild odor

- Low maintenance

- Fast drying

Cons:

- Sensitive to moisture (MVER <3 lbs)

- Cannot use hot pressure washing

- Must wait 5-7 days before heavy-duty traffic and cleaning

Polyurethane, such as KRETUS® Polyurethane

Pros:

- Low to mild odor

- Low maintenance

- Fast drying

- Highest resistance to chemicals like lactic and citric acid

Cons:

- Requires relatively high humidity during application

- Sensitive to moisture (MVER <3 lbs)

- Cannot use hot pressure washing

- Must wait 5-7 days before heavy-duty traffic and cleaning

It’s good to know your options, but before you go out and buy anything, be sure to inspect and test the substrate. This becomes increasingly important in frozen environments because moisture in the concrete expands when it freezes, and it can potentially crack and damage the concrete. The concrete may even require a moisture vapor mitigation system.

Summary

Choosing specialized coatings for cold storage is a savvy move for businesses aiming to preserve product quality and adhere to regulations. These facilities need specialized expertise to uphold optimal conditions and ensure goods remain unspoiled. Choosing and installing the right resinous coating requires careful planning and a high level of technical know-how to meet regulatory standards.

By following the tips shared here and talking with coating experts like the folks at KRETUS® and Jon-Don, businesses can ensure their cold storage facilities are well-coated and maintained, safeguarding temperature-sensitive goods against spoilage and contamination.

Your Source for KRETUS® Products and Training

Jon-Don offers a full selection of high-quality concrete coating products from KRETUS® along with all the essential application supplies contractors need for professional installation. Shop online at jondon.com or call a Jon-Don concrete expert at 800-556-6366.

Looking for training? Register to attend an upcoming Epoxy 101 hands-on training course led by the experts from KRETUS®. Learn how to install KRETUS® coatings in homes, garages, and commercial environments quickly and efficiently. To learn more, check out our course page.

Comments