Spray jets are a common and very important replacement part for carpet cleaning equipment, such as wands and sprayers. These small parts can have a big impact on your cleaning, from the amount of solution sprayed to the chemical applied to how quickly the carpet dries.

In this guide, we’ll dive into the differences between T-jets and V-jets and show you how to choose the right one for your carpet cleaning equipment.

T-Jets & V-Jets – What’s the Difference?

T-jets and V-jets have a lot in common. They produce the same spray pattern, are available in brass or stainless steel, offer a variety of angles, and can have a strainer. So what’s the difference? It comes down to how they are constructed.

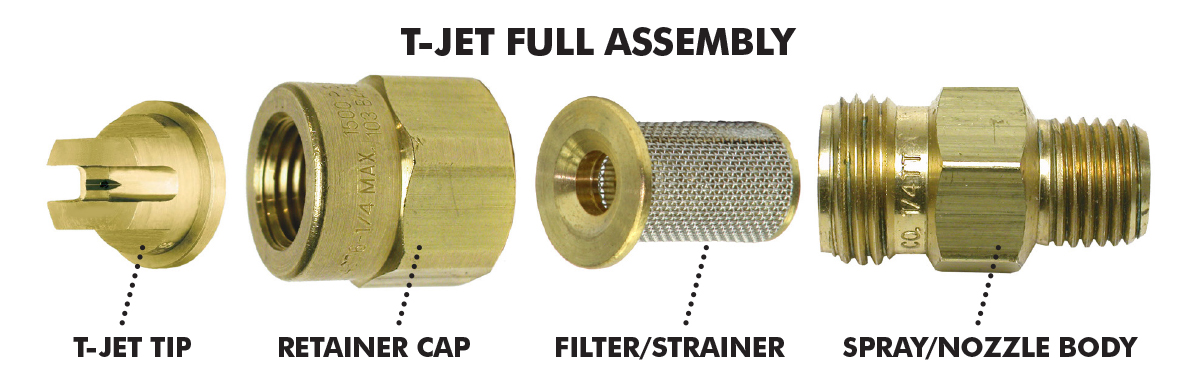

T-jets (or tee-jets) have no thread and must be used with a spray/nozzle body, filter/strainer, and retainer cap. Some users prefer T-jets for the reduced maintenance time as the tip can quickly be replaced by unscrewing the retainer cap while the nozzle body remains in place.

V-jets (or vee-jets) are all one piece that include male threads as part of the jet. V-jets screw directly into the wand manifold.

Is one better than the other? Short answer: not really. V-jets are more often used on low-profile wands, as their shorter length is more compatible. However, T-jets and V-jets are generally interchangeable based on the preference of the user or the recommendation of the equipment manufacturer.

What do the letters and numbers mean on the jets?

All V-jets and T-jets have numbers or a combination of letters and numbers which communicate very important information about the jet.

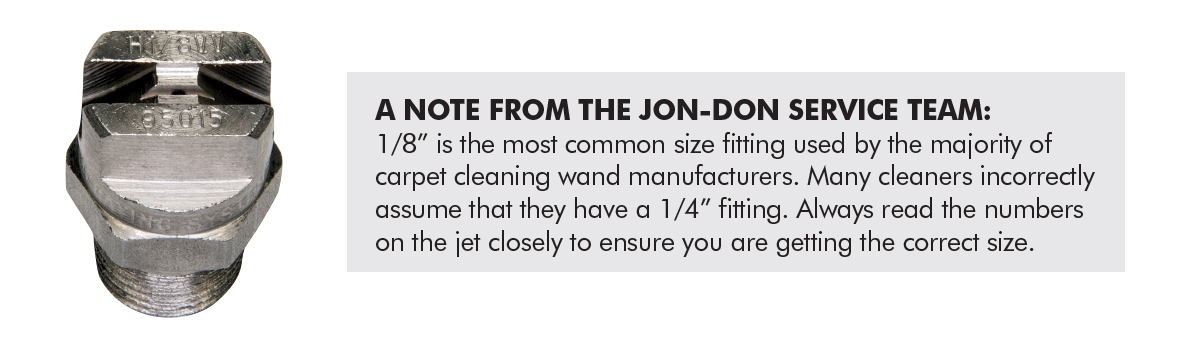

T-jets typically will only display the brand, such as “UNIJET” or “TEEJET” across the top. But V-jets will show a code such as H1/8VV.

This code indicates the size of the fitting and the type of jet.

H1/8 = 1/8” fitting VV = V-jet

All jets will have a series of numbers printed on the lower portion that indicates

- the angle of the spray (which ranges from 0-110 degrees; the higher the number, the wider the spray)

- the orifice size/flow rate (which is measured at gallons per minute at 40 PSI; the higher the number, the more water it will put out).

In the example above, the numbers 95015 break down as follows:

95 = 95-degree angle 015 = 0.15 GPM at 40 PSI (always put the decimal to the right of the zero)

How do angles and flow rate impact your cleaning?

It may be tempting to think that getting the widest angle and highest flow rate jet will result in better cleaning, but that isn’t necessarily the case.

Angles that are too wide will risk spraying past the wand edges, so you may deal with overspray on baseboards or surfaces that you don’t want to get wet.

Higher flow rates mean more water is being put down on the carpet, which means more water needs to be removed through vacuum (extra passes) and evaporation (dry time). If too much water is left on the carpet, you’ll end up with very long dry times, wicking problems, odors, or damage to the subfloor.

Additionally, as the orifice size increases, the temperature of your cleaning solution will decrease. The heater won’t be able to keep up with the additional water flow, so you’ll lose a few degrees. When temperature decreases, you will need to either make additional cleaning passes or increase the dwell time of your cleaning chemical to compensate.

How often should you change out your jets?

Jets are susceptible to a variety of issues that can impact their performance. This can include corrosion, chemical build-up, damage from a wand being dropped on a driveway, or even damage caused by improper cleanout.

Damaged jets can cause streaking, uneven cleaning, heat loss, and flow problems. If you’re experiencing any of these issues, it’s time to swap out your jets.

Our experts recommend that brass jets be replaced about every six months. Stainless steel jets last longer, but generally should be replaced every 12 months for optimal performance.

Which type of jet should I use?

To determine which type of jet is right for your wand, we advise following the manufacturer’s recommendation. They perform hours of testing and review to determine optimal performance, and it’s generally best to stick with what they recommend.

Be sure to check your manual or schematic or contact a Jon-Don rep for guidance on which size jet to use with your equipment. Get free technical advice over the phone or click to chat online or stop in to your local Jon-Don branch to speak with a member of our team.

Get Equipment, Service, and Support from Factory Trained Repair Technicians

Whether your equipment needs routine maintenance or a full-blown repair, our experienced technicians can tackle all your service needs. We fix any make and model, whether you bought it from us or not. Popular services include hose repair, oil changes, winterization, and more!

Call 800-556-6366 to make an appointment or stop by one of our locations today to get your equipment into our experienced hands!

Comments